Airbus’ adjustment of its formidable hydrogen-electric growth program is a testomony to the dimensions of the duty going through the aviation trade to decarbonize.

The information that Airbus is to reduce its ZEROe hydrogen plane growth program was obtained with a mixture of dismay and lack of shock by most within the sector. ZEROe program was launched in 2020 and aimed to place a hydrogen-propulsion plane into service by 2035. As an alternative, there gained’t be an Airbus hydrogen-electric plane flying till 2045, and the variety of engineers engaged on hydrogen R&D globally is being slashed.

Talking on the firm’s 2024 monetary outcomes occasion final month, Airbus CEO Guillaume Faury blamed the cutbacks and delay on the shared lack of progress in growing a hydrogen ecosystem – gasoline manufacturing crops and transmission infrastructure. Primarily, Airbus now believes hydrogen gasoline gained’t be accessible at airports by 2035, making a hydrogen-fuelled plane commercially unviable.

Faury defended the R&D executed thus far, stressing {that a} hydrogen-fuel cell powertrain is technically possible and one of the best ways to attain a zero-emissions plane. Certainly, work on the “crucial applied sciences”, similar to gasoline cells and cryogenic programs will proceed.

However Faury additionally admitted that an eventual hydrogen gasoline cell-powered plane may look very completely different from the ZEROe ideas publicized during the last 5 years. “The plane should make sense by way of measurement, vary and passenger capability for between 2035 and 2045. We should have a look at the whole equation,” he stated.

Small wins

The trade is aware of that hydrogen gasoline cells can energy plane, arguably most credibly due to flight testing achieved by German startup H2fly of its four-seat HY4 demonstrator in September 2023. The plane flew at altitudes of as much as 7,200ft and its longest flight lasted three hours. A modified Pipistrel mild plane, HY4 is powered by cryogenic liquid hydrogen, which may give vary and efficiency equal to fossil fuels minus the carbon emissions.

H2fly was acquired by US eVTOL plane developer Joby in 2021. Elements of H2fly’s propulsion system are being examined in Joby’s eVTOL. H2fly additionally continues to develop its H2F-175 gasoline cell propulsion system, which may output 175kW of energy.

Josef Kallo, now chief expertise officer at H2FLY agrees the most important barrier to utilizing hydrogen in aviation is its manufacturing and distribution. “The principle problem for hydrogen aviation is to construct the infrastructure to make sure a dependable and cost-competitive provide of hydrogen.

“Growing a complete hydrogen ecosystem would require vital funding, significantly in renewable power for inexperienced hydrogen manufacturing and specialised airport refueling infrastructure. This consists of the event of storage and distribution networks to help hydrogen-powered plane.”

“Whereas it’s tough to foretell the precise influence of Airbus’ resolution to reduce its hydrogen R&D efforts, we proceed to consider in hydrogen as an aviation gasoline and are totally dedicated to contributing to the event of a hydrogen ecosystem, beginning with smaller electrical plane.”

Reasonable readjustment

Crucial a part of any hydrogen-electric plane is the gasoline cell. UK-based Clever Vitality already provides hydrogen gasoline cell programs to the automotive, telecoms and development sectors. Based in 2001 and with a workforce in the present day of round 200 folks, the corporate additionally labored with Boeing to construct and fly the world’s first gasoline cell-powered plane in 2008. Jonathon Douglas-Smith, head of aerospace gross sales at Clever Vitality believes most individuals within the trade had been anticipating Airbus to reduce its hydrogen ambitions: “Airbus had been trailblazers with ZEROe. However it’s too giant of an enterprise for them to do all of it themselves,” he says.

“We don’t assume it damages the path to marketplace for hydrogen plane, it’s a realignment that may enable suppliers to assist Airbus make it occur.”

Clever Vitality has developed an aviation gasoline cell as a part of the UK Authorities-funded £54 million (US$68 million) H2GEAR venture. The 300kW succesful gasoline cell system was launched to the market in July 2024 on the Farnborough Airshow. The IE-FLIGHT 300 (F300) is for Half 23 plane with as much as 19 seats and eVTOLs. The primary OEM clients are anticipated to be introduced quickly, with first deliveries deliberate for 2027.

Throughout the subsequent two and half years, engineers at Clever Vitality will develop the steadiness of plant for the F300. This consists of the ancillary components of the system similar to the warmth exchanger, air compressor and hydrogen recirculation module.

Douglas-Smith says, “The market desires a extra full steadiness of plant with the gasoline cell system as a result of it removes the client’s want to grasp the complexities of the best way to run gasoline cells optimally. We now have 24 years of expertise constructing gasoline cell programs, so it is sensible for us to do it.”

Clever Vitality can be growing a bigger F500 gasoline cell system based mostly on the identical underlying light-weight gasoline cell stack expertise for plane bigger than 19 seats. “Scaling up is a part of our roadmap,” says Douglas-Smith. “Bigger plane want the next particular energy, and extra time is required to develop the expertise for these energy densities. We now have R&D packages which can be wanting on the expertise.

“However we see bigger plane as a longer-term market,” he says. “The marketplace for smaller plane will likely be rather a lot sooner, in the direction of the tip of this decade, moderately than the 2040-45 timeframe for gasoline cell powered plane better than 100 seats.”

Clever Vitality has invested closely and made good progress with its aviation gasoline cell, underlining its perception available in the market. Different corporations, similar to Powercell are additionally betting on gasoline cells for aviation purposes. Having provided the gasoline cells for its prototypes, the Swedish firm is supplying the stacks for ZeroAvia’s first 600kW powertrain (ZA600), which can be meant to be used in Half 23 plane.

The 2 corporations are additionally partnering on the R&D for the extra highly effective ZA2000 powertrain, which is aimed toward turboprop plane of as much as 80 seats and will likely be based mostly on Powercell’s heavy-duty gasoline cell stack design. Powercell can be supplying its 300kW HDS300 (heavy obligation system) gasoline cell stack and engineering help for an 18-month aviation venture in Japan.

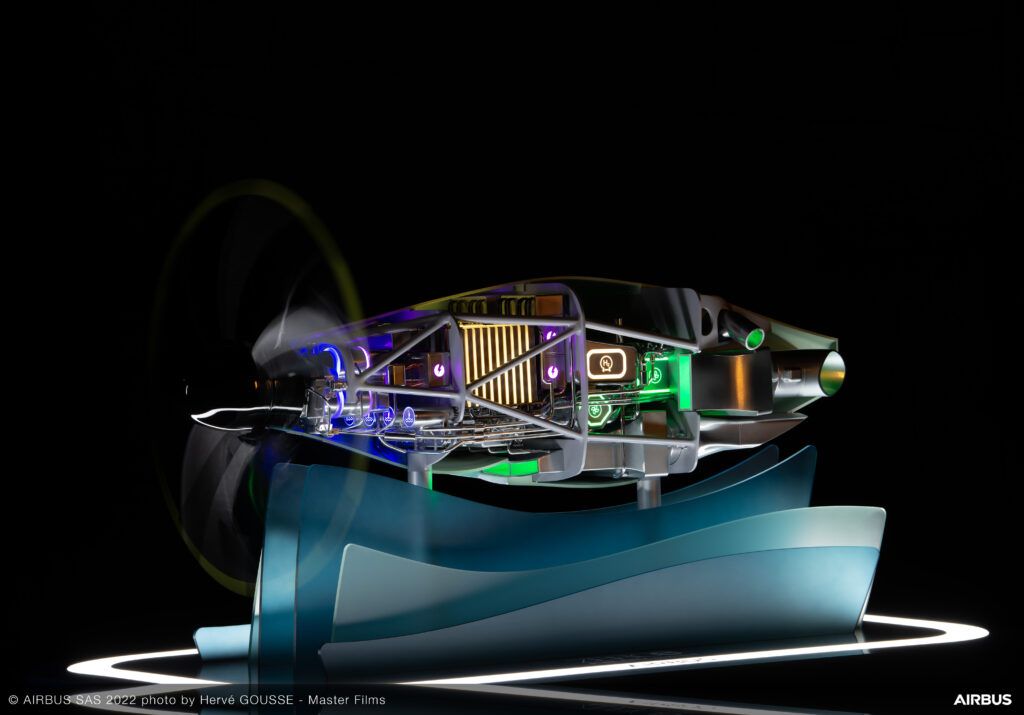

In the meantime, German automotive provider ElringKlinger’s aviation gasoline cell expertise has been licensed by Airbus and is being developed as a part of a three way partnership firm known as Aerostack. Its proton trade membrane (PEM) gasoline cell relies on ElringKlinger’s NM12 stack, which offers a most output of 205kW. The gasoline cells had been utilized in a profitable floor check of a 1.2MW powertrain final January in Ottobrunn, Germany.

“Airbus has acknowledged that important hydrogen gasoline cell part expertise goes to take longer than they anticipated to achieve the efficiency ranges wanted for the 100-seater plane,” says Douglas-Smith. “I’d confidently say that Clever Vitality is a world chief on this area. However there’s a lengthy option to go – the rules and conformity to airworthiness requirements are nonetheless being written by EASA and the FAA – though roadmaps had been revealed by each regulators final yr.”

Warmth dissipation

The H2GEAR venture developed Clever Vitality’s stack expertise to TRL 5. One of many greatest challenges the corporate has encountered with growing gasoline cells to be used in aviation is the high-altitude setting.

“We examined the stack module in consultant circumstances of working altitudes in barometric chambers. The stack was designed to particularly stand up to the stress differentials that may be anticipated at altitude. The seals had been a key a part of the design,” says Douglas-Smith.

“The air is much less dense at altitude, making cooling tougher. We see this already with our merchandise for our drone clients, who use decrease powered cells that includes air-cooling. Our patented evaporative cooling system is extra thermally efficient and one of the best ways to get the warmth out of the stack.”

Gas cells are 50% environment friendly over life. A gasoline cell delivering 100kW of energy produces 100kW of warmth which must be dissipated. The Flight F300’s evaporative cooling system injects deionized water into the highly regarded stack, which evaporates. Warmth is transferred by vaporization, which is a more practical manner of eradicating warmth from the cells than liquid cooling.

Crucially for aviation purposes, the elevated effectiveness of evaporative cooling allows the thermal administration system to be smaller and lighter. Injecting water straight additionally humidifies it, which optimizes the efficiency and lifelong of the stack.

Now-defunct hydrogen aviation startup Common Hydrogen used USA firm PlugPower’s automotive gasoline cell for its testing program, integrating a system into the nacelle of a Sprint 8 plane. Specialists had been fast to see the cooling challenges that had been encountered by the Common Hydrogen crew. “They wanted actually giant air scoops and radiators, including weight and drag. It grew to become apparent it wasn’t a viable resolution to go to market with,” says Douglas-Smith.

“That was one of many motivations for us to develop the F300, which past the evaporatively cooled expertise, has a excessive temperature that may additional shrink the thermal administration and nacelle packaging. That’s one of many core growth actions now.”

Energy distribution programs

GKN Aerospace heads up the H2GEAR program, which began in 2020 and concludes in September this yr. H2GEAR goals to develop a liquid hydrogen propulsion system for sub-regional plane that may be scaled as much as bigger plane. It’s the largest single program ever awarded by UK funding physique the Aerospace Expertise Institute (ATI). In addition to gasoline cell firm Clever Vitality, companions embody turbocompressor firm Aeristech and a number of other analysis universities.

H2GEAR is reaching its demonstration and testing part. ATI has awarded GKN different hydrogen analysis packages, together with the £40 million, four-year HyFIVE program, which focuses on liquid hydrogen storage and gasoline conditioning programs, and the £44 million H2FlyGHT, a follow-on to H2GEAR. H2FlyGHT goals to exhibit a 2MW hydrogen-electric propulsion system in flight by the tip of the last decade.

Mike Hales, chief engineer of hydrogen propulsion at GKN Aerospace says, “At its coronary heart we’re constructing an power conversion system – liquid hydrogen is transformed into DC energy by way of a gasoline cell, then distributed across the plane and offers the propulsion energy.

“It’s transformed to AC energy in an inverter positioned subsequent to {the electrical} machine, which converts that into torque to run the propulsor. The powertrain could be comparable if you happen to had been utilizing GH2 as a gasoline supply, however the H2GEAR structure with an LH2 gasoline supply to supply some preferential technical options.”

“It’s transformed to AC energy in an inverter positioned subsequent to {the electrical} machine, which converts that into torque to run the propulsor. The powertrain could be the identical if you happen to had been utilizing GH2.”

Hales believes the 50% gasoline cell effectivity achievable in the present day might be improved upon by advances in chemistry growth and supplies expertise. Hyperconducting supplies are getting used within the DC energy distribution system and {the electrical} machine’s stator. These behave equally to superconductors however use metals similar to high-purity aluminum, giving low resistivity at cryogenic temperatures with out the abrupt failure dangers of superconductors. “Hyperconductors are additionally an obtainable near-term expertise and might be made reliably in the present day within the kind we require,” says Hales.

The decreased energy losses within the distribution system imply extra present might be transferred. Chunky copper cables might be changed with smaller conductors and a decrease voltage to cut back the load by as much as 4 instances. It may possibly use a +/- 270V customary, already in use in the present day can be used and minimizes the partial discharge results.

The decreased energy losses within the distribution system imply extra present might be transferred. Chunky copper cables might be changed with smaller conductors and a decrease voltage to cut back the load by as much as 4 instances. The expertise allows using a +/- 270V customary, already in use in the present day.

“Cryogenic cooling permits us to enhance the effectivity of energy distribution and propulsion. With hyperconducting supplies, we see round a ten% enchancment in electrical switch effectivity, which straight interprets right into a smaller and lighter system for a given energy,” says Hales. “By cooling {the electrical} machine’s stator windings to cryogenic temperatures, we dramatically scale back AC and DC losses. This enhances effectivity and helps us hold the system compact.”

H2gear testing

Researchers on H2GEAR are integrating programs and have been testing gasoline cells because the finish of 2023. “An enormous milestone final yr was the meeting of our first demonstrator motor. It’s the primary machine of its sort that accommodates hyperconducting high-purity aluminum. That motor has been on check on the College of Manchester. We’re growing its shaft energy to confirm its effectivity.”

GKN researchers have designed a number of ideas, together with a notional research plane that will be used as a reference from which to check the powertrain in simulation.

“Our analysis signifies that hydrogen-electric propulsion gives a pathway to zero-emission plane. By leveraging cryogenic and hyperconducting applied sciences, we will enhance vary functionality.

“With projected enhancements in gasoline cells and different components, we consider it’s possible to scale as much as single aisle sized plane. That might make a significant influence on the aviation trade’s emissions footprint.”

Regardless of additionally being a part of the H2GEAR program, GKN won’t be utilizing Clever Vitality’s F300 gasoline cell, as a result of its growth roadmap targets plane of greater than 100 seats, like Airbus’ plan.

“Gas cell expertise has solely actually been in growth for aerospace for the final 5 years,” says Douglas-Smith. “There’s uncertainty about its limits. It may be capped at 100 or 120-seat plane. Proper now, all we all know for certain is it really works for smaller plane and eVTOLs.”

Equally to battery-electric plane, the trail to marketplace for hydrogen-electric will construct from smaller, basic aviation plane to regional plane after which, maybe on to giant airliners. Even then, the viability depends upon a large cross-sector effort to ascertain sustainable methods of manufacturing and distributing hydrogen gasoline and new swathes of regulation. As Airbus has labored out, there isn’t a shortcut to hydrogen aviation.

On-aircraft challenges

Thermal points will not be the one concern when integrating a hydrogen-electric gasoline cell powertrain into an plane. Dr Craig Lawson is a reader in airframe programs at Cranfield College. Final month floor was damaged on the College’s £69 million (US$87 million) Hydrogen Integration Incubator (CH2i) venture, which will likely be one of many largest hydrogen R&D services in Europe. “The introduction of hydrogen is so radical it would doubtless be executed incrementally and at first sub-optimally. One of many massive points is storage quantity,” he says. “With a tube and wing design, you may’t put hydrogen gasoline within the wings as a result of they’re too skinny. We’d like cylindrical, ideally spherical tanks. You may put them within the fuselage, however then you’re compromising on passenger house and payload.”

In line with Lawson research modifying present plane with hydrogen gasoline programs have concluded the consequence will likely be plane with inferior payload and vary capabilities in comparison with present fashions. “We’re going to have to just accept a success on payload and vary to have a zero-carbon plane,” he says.

As well as, a change in power service means large adjustments to certification and rules. The protection case for hydrogen as an aviation gasoline is but to be totally explored.

“We perceive the failure modes of kerosene, so it’s OK to have it comparatively close to an plane’s occupants. However it’s not clear that the failure mode of a hydrogen tank goes to be something aside from catastrophic,” says Lawson.

“Which means to some folks, if the hydrogen is throughout the similar fuselage because the occupants, the plane is uncertifiable as a result of any failure goes to be catastrophic.”

Hydrogen could possibly be saved on tanks mounted on wings, however once more this can be a sub-optimal resolution. Alternatively in a blended wing physique (BWB) plane, which options plenty of storage quantity, the hydrogen tanks could possibly be positioned outboard of the passengers. “BWB might be the most effective resolution for a hydrogen airliner,” says Lawson.

BWB is an immature design, though research have proven it to be environment friendly for large-capacity plane, it doesn’t matter what the power service, says Lawson. Nevertheless, curiosity is rising in BWB, due to the push in the direction of hydrogen as a gasoline. California, USA-based startup JetZero plans to begin flight testing a full-scale BWB plane in 2027. “There’s analysis coming in Europe and our Exaelia venture has simply began, lengthy vary, A350 replacements – inexperienced airliners,” says Lawson.