The dry electrode coating course of has the potential to allow the manufacturing of higher, greener, cheaper batteries. It depends on superior fluoropolymer binders with Teflon™

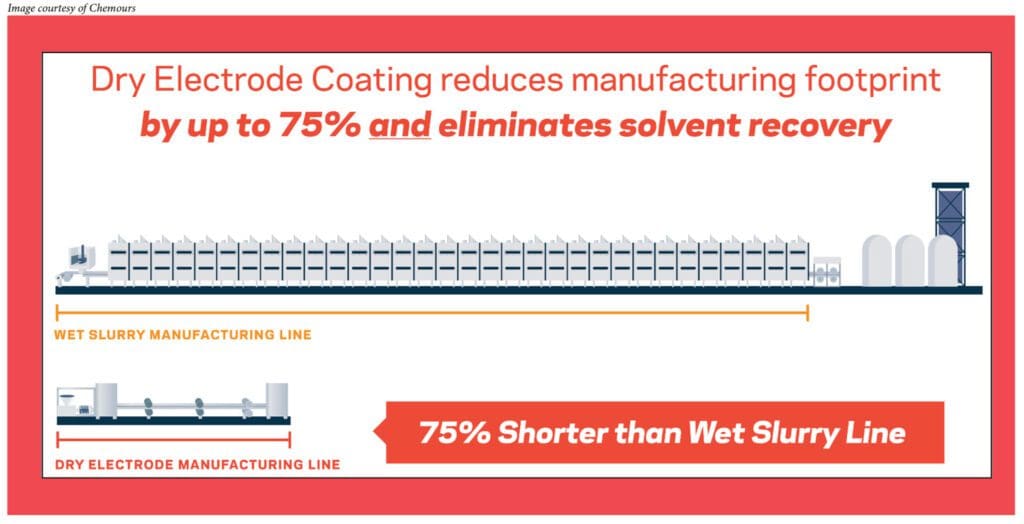

For a number of years now, Charged has been reporting on how dry electrode coating processes have the potential to revolutionize battery manufacturing by eliminating using hazardous, environmentally dangerous solvents. Taking the solvents out of the method can translate to large financial savings in price and flooring house within the manufacturing facility—and the dry coating course of can even allow designers to enhance battery efficiency.

The dry electrode coating course of depends on using particular binders that may type an electrode coating with out being dissolved in a solvent, corresponding to fluoropolymer binders with Teflon™ from specialty chemical firm Chemours.

To study the benefits of the dry coating course of, and the way corporations are assembly the challenges concerned in scaling the know-how up from pilot to manufacturing scale, Charged spoke with Tejas Upasani, International EV Know-how Supervisor at Chemours.

Tejas Upasani: We wish to name Chemours “a startup firm with 200 years of historical past.” We spun out of DuPont in 2015, and now we have main manufacturers in numerous industries, together with semiconductors and automotive. Beneath our Superior Efficiency Supplies enterprise, now we have manufacturers you may acknowledge, corresponding to Teflon™, Nafion™ and Viton™.

Now we’re experiencing development in our merchandise in a brand-new discipline—the dry electrode coating course of—and I’m actually excited to see how Chemours can assist the scale-up of this new utility.

Within the dry course of, lots of the elements stay the identical—related energetic supplies, related conductive components. What actually modifications is the binder.

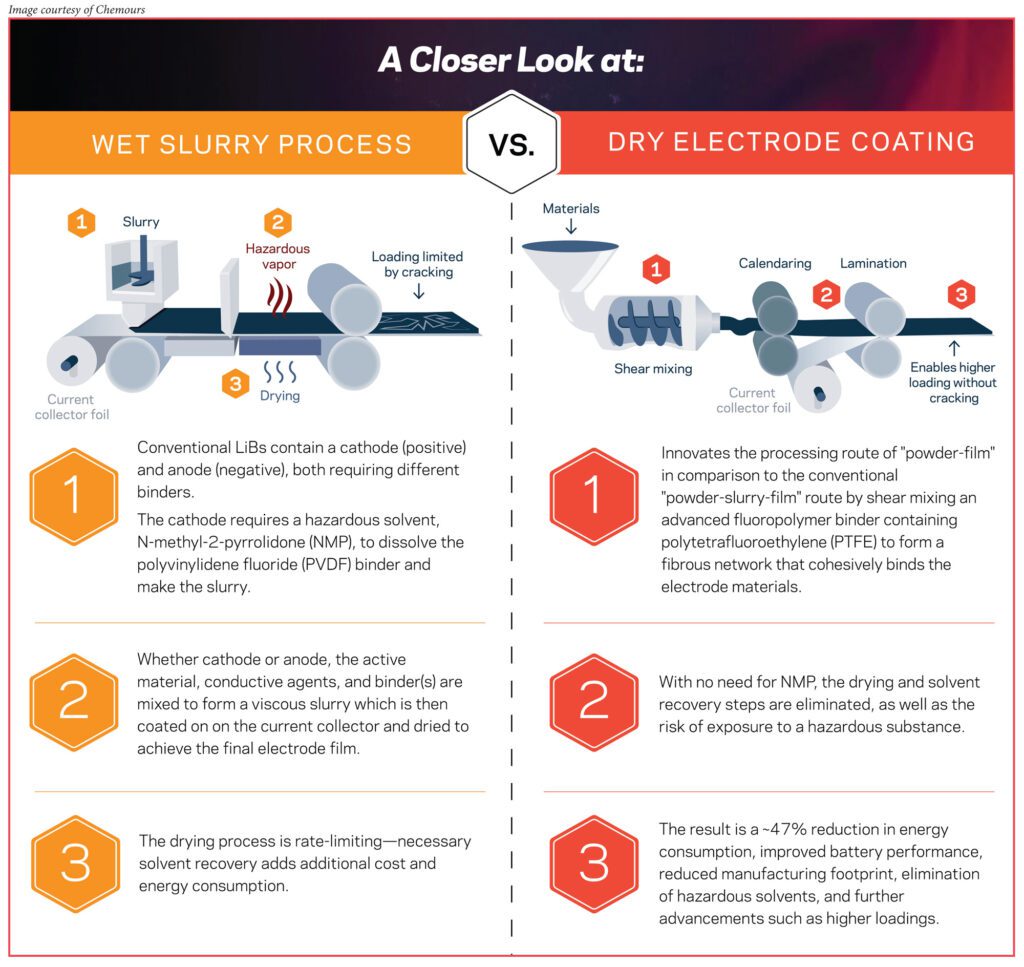

Charged: Are you able to stroll us by way of the essential benefits of the dry electrode coating course of versus the normal moist slurry-based course of?

Tejas Upasani: The dry coating course of is a novel means of producing cathode and anode electrodes in lithium batteries.

Within the conventional moist slurry course of, now we have the energetic elements, now we have the conductive components, and we use a selected binder which must be dissolved in a solvent. As soon as all these elements are combined collectively, we create what is named a slurry. That slurry needs to be coated onto a present collector. At that time, the perform of the solvent is completed, so we dry off the solvent and we get a pleasant coating on the present collector.

Within the dry course of, lots of the elements stay the identical—related energetic supplies, related conductive components. What actually modifications is the binder. On this case, we’ll be utilizing superior fluoropolymer binders with Teflon™ which, due to its distinctive properties, doesn’t have to be dissolved in any solvent. It might type the coating because it goes by way of the processing steps by way of a course of known as fibrillation, which mainly kinds all the coating on the present collector.

Why is the dry course of advantageous over the moist slurry course of? We will take a look at this from three completely different angles.

One is that it’s way more environmentally pleasant. The moist slurry course of makes use of NMP [N-Methylpyrrolidone], which is a hazardous solvent. In an effort to do away with the solvent within the moist slurry course of, it has to undergo a collection of ovens. If there isn’t any want for the solvent, then the hazards related to the solvent are eliminated.

The second half is manufacturing prices. For those who take a look at how a lot house is required for the moist slurry course of, by some estimates, it’s 10 occasions the house in comparison with the dry course of, so there’s an amazing quantity of financial savings of flooring house that may be achieved with the dry course of.

The third side is that it permits higher efficiency of the batteries. With the dry course of, we will make thicker electrodes, which might help with enhancing energy density.

Superior fluoropolymer binders from Chemours are actually on the coronary heart and heart of that course of.

Charged: Is that this one thing that would assist to scale back charging occasions?

Tejas Upasani: It probably may. There’s quite a lot of testing that’s being carried out proper now, evaluating the moist slurry course of and the dry course of. If you’ll be able to go to the next loading with the dry electrode course of—say, all the best way to eight or 9 milliamp-hours per sq. centimeter—we will see aggressive or increased charging charges in comparison with a traditional loading of the moist slurry course of, which is about 3 to 4 milliamp-hours per sq. centimeter now. A lot of this work is completed at lab scale or pilot scale, however because the know-how matures and we begin seeing higher course of applied sciences, these will be realized in real-life eventualities as effectively.

Charged: Is dry electrode coating at the moment in manufacturing?

Tejas Upasani: We’re within the early levels of the event course of. Some {industry} gamers are at manufacturing scale. For instance, on Battery Day in 2020, Tesla introduced that they wished to supply their 4680 cells in a dry electrode course of. And on Investor Day in 2023, the corporate introduced that they’d efficiently applied industrial manufacturing of the dry electrode course of. PowerCo, a subsidiary of Volkswagen, has introduced that they are going to deploy and commercialize the dry electrode course of at many alternative places. LG Vitality Options has introduced related plans.

However because it stands proper now, we’re seeing all the spectrum—lab, pilot, pre-production, manufacturing—of adoption of the dry electrode course of.

We predict that cell producers and OEMs within the subsequent two to 5 years are going to be in numerous levels. Some are going to be at pilot scale. Others are going to advance into manufacturing scale. However because it stands proper now, we’re seeing all the spectrum—lab, pilot, pre-production, manufacturing—of adoption of the dry electrode course of.

Charged: Are there any main technical hurdles that we nonetheless must get previous earlier than this may be broadly adopted?

Tejas Upasani: Actually there are hurdles. All people’s making an attempt to develop the method, and so they’re making an attempt to make it possible for the right mixing and calendaring will be carried out with the intention to create a uniform construction. A few of the technical hurdles must do with binders and the dry electrode processes enabled by way of understanding the fibril community of PTFE [polytetrafluoroethylene].

Using PTFE and the resultant fibril community has been understood for many years, and we, as inventors of PTFE, have invested quite a lot of science behind understanding the fibril community, however it typically has been utilized to industries the place PTFE is the dominant part within the utility. For example, for those who take a look at your normal plumber’s tape (Teflon™ tape), it makes use of precisely the identical precept of fibrillation. That’s why you possibly can pull it in a single course simply, however within the transverse course, you possibly can simply break it aside.

It’s the identical on this utility—we’re making an attempt to regulate the fibrillation by way of the blending course of and thru the calendaring course of. Chemours has invested closely in creating numerous forms of superior fluoropolymer binders with PTFE. These have a variety of various molecular weights and completely different polymer architectures, and all of those are supposed to allow the right fibrillation traits throughout the electrode course of.

On the cathode aspect, typically PTFE is oxidatively very steady…it’s a really promising utility. On the anode aspect there is perhaps reductive stability challenges related to conventional PTFE, and so utilizing conventional PTFEs won’t be the optimum resolution.

Conventional PTFE might have challenges on the anode aspect. On the cathode aspect, typically PTFE is oxidatively very steady. One of many benefits is which you could go to increased voltages and it nonetheless is steady at higher-voltage functions. So, on the cathode aspect, it’s a really promising utility.

On the anode aspect there is perhaps reductive stability challenges related to conventional PTFE, and so utilizing conventional PTFEs won’t be the optimum resolution. That’s one of many the explanation why we’re creating quite a lot of completely different merchandise and making an attempt to grasp the mechanism of why conventional PTFE is just not steady on the anode aspect. And as soon as we perceive that mechanism, how can we remedy that? There’s an amazing quantity of labor happening internally and with our exterior companions as effectively to try to perceive and remedy these hurdles.

Charged: One of many challenges is adhesion. The dry materials has to bond to the electrode floor, however the flat floor and lack of texture could make that tough.

Tejas Upasani: The {industry} proper now could be utilizing what we name carbon-coated present collectors. They’ve sure coatings on the present collectors, and when the dry course of movies are made, these get laminated onto that carbon-coated present collector.

That’s the answer that the {industry} has at this level, and it’s working pretty effectively in each anode and cathode processes. Now, if we wished to straight laminate the movie onto the present collector with none carbon coating, then that’s a bit of little bit of an issue, and we’re engaged on it proper now.

We’re taking a look at ways in which we will alter the chemistry of the polymers themselves with the intention to get higher adhesion to the present collectors. If we have been capable of straight laminate onto the present collector, why have this carbon coating?

We’re taking a look at ways in which we will alter the chemistry of the polymers themselves with the intention to get higher adhesion to the present collectors. If we have been capable of straight laminate onto the present collector, why have this carbon coating? Eliminating the coating reduces the price. I feel which may come, however proper now the main focus is on scaling up the know-how with coated present collectors.

Charged: The method wants to scale back the quantity of binder and different inactive materials to an analogous degree as that of moist coating, however this may be costly and laborious to scale up.

Tejas Upasani: Yeah. Sure cell chemistries require rising the quantity of inactive materials, particularly on the cathode aspect, whereas there are some cell chemistries the place we’re taking a look at binder loadings of lower than 2%, and in some instances even lower than 1%.

So, it’s already being labored on, making an attempt to scale back the quantity of inactive supplies. It does require quite a lot of course of optimization as a result of, as you possibly can think about, the small quantity of binder is holding up all the powder chemistry. So, quite a lot of course of know-how, together with the fabric enhancements that we’re doing in creating new supplies and developing with completely different polymer chemistries, goes to allow even additional reductions of the quantity of inactive supplies.

Charged: One other problem is uniformity—the dry coating combination must be uniform throughout giant areas of the battery electrodes.

Tejas Upasani: I don’t assume uniformity challenges are essentially restricted to the dry coating course of. There are strategies which were developed within the moist slurry course of to grasp that the viscosity is true or the solids content material is true, and that can assist us to grasp that the uniformity of the slurry can also be good.

As soon as the blending is completed homogeneously, the great thing about the dry electrode course of is that, as soon as it’s laminated onto the present collector, the coating course of is completed. You don’t have any motion or settling of the elements.

Within the dry course of, it’s related, besides that we’re coping with all of the powders. There are analytical strategies and instruments which might be being developed with the intention to confirm that these powders are combined accurately—the energetic supplies, carbon black and binders, they have to be combined actually homogeneously. As soon as the blending is completed homogeneously, the great thing about the dry electrode course of is that, as soon as it’s laminated onto the present collector, the coating course of is completed. You don’t have any motion or settling of the elements. In a moist slurry course of, for those who have been to make a thick electrode, because the solvent is drying off, these elements might begin to settle throughout the drying course of.

Charged: So, your organization would associate with the producer to find out the perfect combine.

Tejas Upasani: Sure. And all through our historical past, now we have checked out utility improvement. That is what now we have carried out at Chemours for many years. We don’t need to simply say to the purchasers, “Right here’s a fabric, use it.” We don’t need to say that we’re only a provider. We don’t need to cease there. We need to make it possible for we contribute to the success of our prospects as effectively.

There are strategies accessible to grasp the blending homogeneity, that are very R&D-based, and we’re doing a few of that work, but when somebody is doing this on a manufacturing foundation at a producing website, they aren’t going to have time to take a pattern, go into the R&D lab and anticipate days with the intention to get the outcomes. So, after we are creating these strategies internally, we are attempting to develop a technique which goes to be consistent with manufacturing characterization and evaluation.

Charged: Are you able to inform us about your superior fluoropolymer binders with Teflon PTFE?

Tejas Upasani: Understanding the fibrillation traits is basically the important thing in enabling the dry electrode course of. We’ve got a spectrum of various merchandise, which can be found to be utilized in a batch mixing course of, or in a steady mixing course of. Not all of our prospects are going to make use of the very same means of producing it, so making an attempt to tailor our merchandise to their wants is the important thing.

And on condition that now we have tried all different types of chemistries for our superior fluoropolymer binder merchandise, it’s simpler for us to grasp what precisely goes to have an effect on the fibrillation traits, and consequently the mechanical properties of those supplies.

Additionally, Chemours is the one fluoropolymer producer who has manufacturing websites in all three main areas—the US, Europe and Asia/Pacific. After we take into consideration a situation the place the manufacturing goes to be scaled as much as a manufacturing scale, now we have the flexibleness of getting the merchandise being made at completely different places and supporting our prospects with the identical high quality, the identical security requirements and identical requirements utilized to accountable manufacturing.

Charged: We’ve heard about some proposed laws in Europe round PFAS that would influence PTFE. What influence would this have on dry electrode coating?

Tejas Upasani: I’m glad that you simply requested the query, as a result of generally it’s the elephant within the room after we are speaking with our {industry} companions.

We at Chemours firmly imagine that our fluoropolymers will be manufactured responsibly, and we’re in favor of industry-wide nationwide laws and testing necessities, that are primarily based on science and details—data-driven laws and testing strategies, we’re utterly in favor of that.

We spend quite a lot of time, cash and sources in figuring out the sources of emissions from manufacturing fluoropolymers, and putting in abatement methods with the intention to management these emissions. We’re additionally partaking closely in making an attempt to develop alternate manufacturing applied sciences. All of those are steps that we’re taking with the intention to meet the wants of potential regulation.

If we take a look at the EU laws, significantly, it’s not essentially confined to PTFE. PVDF, which is a fluoropolymer used within the moist slurry course of, may be probably impacted by the identical laws.

Fluoropolymers generally are important to lithium-ion batteries, and so they’re important for us to transition to a clear vitality surroundings. So, we need to be companions within the regulation to make it possible for the laws deal with the considerations, and that these merchandise are manufactured in a accountable means, and we’re dedicated to doing each issues.

This text first appeared in Problem 69: July-September 2024 – Subscribe now.