As we enter the second month of 2025, Honda is inching nearer to commencing BEV manufacturing at its long-standing US plant in Marysville, Ohio, later this yr. That $1 billion transition will start with the meeting of the just lately confirmed Acura RSX EV, adopted by the primary two fashions in Honda’s 0 Collection lineup. Earlier than that occurred, nonetheless, Honda gave an unique tour of its new EV Hub in Ohio, which included an progressive new strategy to modular automobile meeting, huge mega press machines, and an insightful look into the constructive impression Honda has established amongst the residents of The Buckeye State. You’ll be able to view my entire tour expeirience within the video beneath.

Whereas Honda is a worldwide identify synonymous with engines and mobility, it’s nonetheless carving out its personal legacy within the BEV phase. That course of started with two preliminary all-electric fashions – the Honda Prologue and the Acura ZDX, each of which I’ve had the chance to check drive and share my impressions.

Whereas these two fashions put a few of Honda’s pores and skin within the recreation, they’re arguably solely a fraction of Honda’s true design DNA, which it has since taken into its personal fingers wanting ahead. That future contains the Honda 0 Collection, which was initially introduced at CES 2024 as a “again to zero” mentality for the Japanese automaker.

The 0 Collection started with two BEV ideas known as the “Saloon” and “Area Hub,” which have since developed within the Honda 0 Saloon and SUV prototypes, which debuted at CES a yr later and had been on show at Honda’s EV Hub in Marysville, Ohio this previous week.

Marysville, dwelling to Honda’s first and longest-running US manufacturing facility, will quickly home BEV manufacturing of the 2 fashions talked about above. First, nonetheless, Honda will start assembling an all-electric Acura SUV developed from the Efficiency EV Idea, which we just lately realized will probably be known as the RSX.

Honda continues to be placing the ending touches on a $1 billion overhaul of its new EV Hub in Ohio however invited a bunch of media out to tour a number of services and see the place the primary true Honda and Acura-built BEVs will probably be assembled, starting later this yr.

I documented my go to in a video beneath, however will break it down in phrases for you as properly.

Honda is taking a failsafe strategy to manufacturing

As you might or might not know, the Honda EV Hub is a part of a $1 billion+ funding from the Japanese automaker to retool its present services in Ohio to provide electrical automobiles. That features reimagining three present vegetation: the Marysville Auto Plant (MAP), East Liberty Auto Plant (ELP), and the Anna Engine Plant (AEP).

Throughout my EV Hub go to, we began on the Marysville Auto Plant, which initially opened in 1979 and has been constructing Honda automobiles since 1982, to see the progress the corporate has made in revamping a 40+ yr previous facility for the all-electric age whereas persevering with to construct ICE and plug-in automobiles.

What we noticed was a singular strategy to modern-day automobile meeting, wherein Honda will quickly be capable to construct ICE, hybrid-electric, and BEVs on the identical manufacturing line. Moreover, the automaker can ramp up or down any particular automobile configuration relying on buyer demand. Senior vp, Honda Improvement & Manufacturing of America, LLC, Bob Schwyn spoke to the media earlier than becoming a member of us on the tour of Marysville:

The Honda EV Hub offers Honda with the pliability to provide ICE, hybrid-electric and EV fashions on the identical manufacturing traces so we are able to rapidly reply to shifting buyer wants and market circumstances. Past including the potential to provide EVs, we fully reimagined our strategy to manufacturing, remodeling the Honda manufacturing setting with extra human-friendly processes and sustainable manufacturing practices.

As you’ll see in my video protection, Honda was within the technique of constructing a slew of Accords, which was attention-grabbing in its personal proper, however what was extra thrilling was the empty area on the Marysville part of the EV Hub, the place Honda will quickly start assembling its battery platforms earlier than integrating them into automobiles on these exact same meeting traces, starting with the Acura RSX.

As you may see within the picture beneath, Honda has cleared out a large quantity of area for devoted BEV element meeting, which required it to take away a complete present construct line and get inventive about the place to re-implement different manufacturing elements in several components of the plant – all whereas persevering with to construct non-BEV fashions.

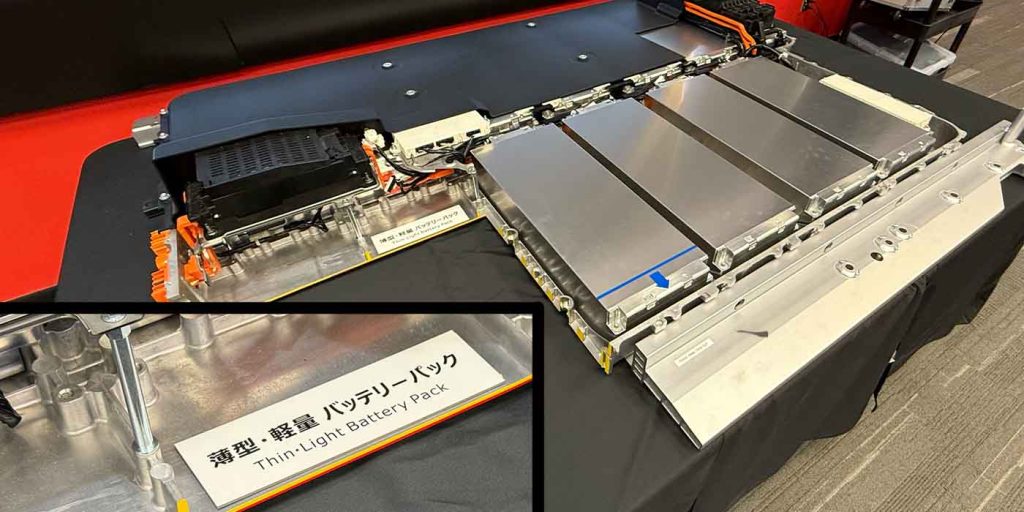

Per the Honda workforce, the EV Hub will rent 300 new staff to particularly deal with battery pack meeting at Marysville. The battery instances for these packs are constructed at Honda’s Anna Engine Plant, which I additionally received to go to and have detailed beneath. These manufactured instances are then transported to Marysville, the place educated Honda “Associates” will work alongside electrical guided automobiles (EGVs) and robots to assemble Honda’s first-ever propriety EV platform.

Honda calls the method “Parallel module manufacturing,” which consists of a community of meeting cells performing meeting duties in a multi-lateral method wherein if one cell is sluggish or fully down for some purpose, manufacturing can proceed.

Per Honda, the primary batch of battery pack meeting cells have been put in at Marysville with a second batch to observe in three months. That can put Honda at its focused launch quantity of which it could possibly scale from there relying on demand.

Honda’s megacast arsenal bolsters EV Hub’s future

After our walkthrough round Marysville, we took a bus journey to Anna, Ohio, dwelling to Honda’s Anna Engine Plant – one other key piece to its EV Hub. Regardless of its identify, Honda doesn’t simply construct engines in Anna. Sure, it nonetheless very a lot does, however AEP can be the brand new dwelling to very important equipment in Honda’s BEV manufacturing.

Honda has put in 5 of its six deliberate 6,000-ton megacasting machines at AEP, which can die-cast the EV battery instances talked about above and seen within the photos beneath. The huge die-cast machines, every able to 300 tons of stress throughout a trim press, will probably be operated in pairs by Honda as quickly because the final machine has been put in.

With the intention to transfer the megacasting machines into the Anna Engine Plant, Honda needed to widen its plant door. Then, it put in machines one by 4, adopted by quantity six, which simply began operations a few weeks in the past. Machine 5, which might have been in the best way if it hadn’t been put in final, will probably be arriving quickly with loads of time earlier than Acura RSX manufacturing begins.

For me personally, it was superior to go to AEP and see the megacasting in motion as a result of I received to see the identical machine at Honda’s R&D heart in Tochigi, Japan, this previous fall. There, I used to be informed that six extra of these megacasting machines could be put in on the EV hub in Ohio.

Simply months later, Honda is sort of full with the set up course of, and the three pairs will start urgent the entrance and rear battery casings. Whereas I did see the megacast machine in motion in Japan, it was at a distance. Throughout my go to to the EV Hub, nonetheless, Honda took us onto one of many machines the place we might watch an EV battery case forged and trimmed up shut. I documented it in my video beneath for you!

One other meeting method I realized about in Tochigi however received to see in individual on the Anna Engine Plant was Honda’s friction stir welding course of. This progressive methodology produced high-strength welds to mix the 2 halves of the battery case and the water jacket (seen beneath) whereas lowering the quantity of power used and warmth impression on the aluminum materials.

This method and Honda’s total EV Hub renovation are half of a bigger three-pronged technique known as “Triple Motion to Zero.” Its purpose is to realize zero environmental impression by 2050 by carbon neutrality, clear power, and useful resource circulation. That entails all zero-emission gross sales by 2040.

Honda is constructing EVs within the US the best manner

After my go to to Marysville and Anna, strolling the meeting traces and chatting with Honda Associates from all ranges of the corporate, I noticed {that a} vestige of the American dream continues to be current in Ohio. Marysville and Anna are blue-collar areas, and people cities have continued to evolve because of Honda’s determination to plant roots on US soil over 40 years in the past.

Lots of the folks I encountered throughout my journey have been with the corporate for longer than I’ve been on this Earth, some second technology, who grew up watching their mum or dad develop alongside the corporate and its Ohio footprint.

Whereas a lot of Honda’s US manufacturing historical past is a bit oily and dusty because of engines and combustion, the EV Hub offers a brand new period on par with Honda’s total “again to zero” startup mentality. I used to be genuinely impressed by Honda’s skill to pivot, rethink, and repurpose its present services to help the addition of BEV manufacturing.

Moreover, the choice to implement these assemblies on the identical line as Honda’s ICE and plug-in automobiles feels like a pipe dream on paper, however in individual, the corporate seems to have pulled it off. However it took everybody in Marysville, East Liberty, and Anna to get there. Honda will proceed to depend on these Associates because it approaches the day when its first bespoke BEV on its very personal platform rolls off that Marysville meeting line.

With the present political local weather and EV training and understanding remaining big hurdles for People and loads of the general public servants who assist govern them, the way forward for BEV manufacturing is murky. That’s scary, given our super progress up to now decade.

Nonetheless, whether or not persons are shopping for ICE automobiles, hybrids, PHEVs, or BEVs years from now, Honda has teed itself as much as adapt and rise to the problem (one thing the corporate prides itself on) with its EV Hub.

I’ve now realized the the place, the when, and the how of BEV manufacturing on the Honda EV Hub, however now I’m prepared for the what. From what I’ve been informed, the 0 Collection Saloon and SUV prototypes are “very shut” to the ultimate manufacturing design, however the Acura RSX stays a little bit of a thriller except for one camouflaged picture.

I anticipate to be taught extra quickly as that SUV will kick off Honda’s EV Hub manufacturing in late 2025. Maybe I can take one other journey to Ohio and see it constructed earlier than driving one myself. Whereas we await that milestone, you may take a look at my video touring the Marysville and Anna services at Honda’s EV Hub beneath:

FTC: We use revenue incomes auto affiliate hyperlinks. Extra.